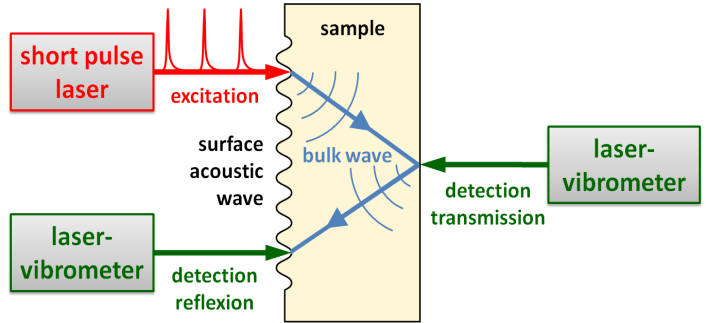

Laser ultrasonic testing is able to remotely generate ultrasound in materials without contact leaves a very small footprint so that it can be applied to irregular geometries and.

Laser ultrasonic ndt.

Laser ultrasonics may not quite be the buzz word in nondestructive testing ndt yet but a handful of industries have recognized its benefits and have implemented a.

We primarily serve the defense aerospace and energy industries providing standard products and custom systems for a wide variety of applications.

The laser pulse strikes the component generating ultrasonic waves through a thermoelastic process or by ablation.

To cope with the developments of new structures and to reduce the constraints and costs of non destructive testing ndt aircraft manufacturers have to constantly look for and develop innovative testing methods.

As shown laser pulses can generate the full complement of waves longitudinal shear surface and plate.

Laser ultrasonics is a cutting edge non destructive testing ndt method in which lasers are used to generate and then measure ultrasonic waves in a material.

Lut systems first generate ultrasonic waves from a pulsed laser.

Laser ultrasonic testing lut is a non contact nondestructive inspection technology that that uses lasers to generate and detect ultrasonic waves in the component under test.

Par systems is the only company in the world that builds laser ultrasonic systems specifically configured to efficiently analyze aerospace components.

Laser ultrasonics r tuis air.