Kossowsky laser beam welding of aluminum alloy plates 7039 5083 and 2090 in proceeding of the international congress on applications of lasers and electro optics icaleo 89 pp.

Laser beam welding aluminium.

Laser stands for l ight a mplification by s timulated e mission of r adiation.

Laser beam welding is a technique in manufacturing whereby two or more pieces of material usually metal are joined by together through use of a laser beam.

As a result it is possible to couple the energy much more efficiently using electron beam welding compared to laser welding.

Aluminum is one of the easiest metals to penetrate with an electron beam.

Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.

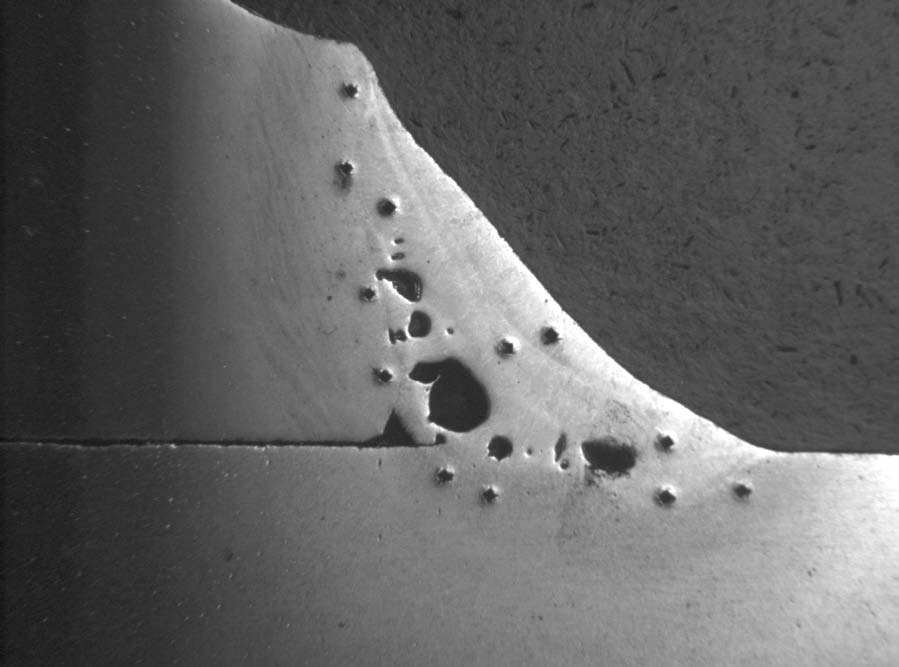

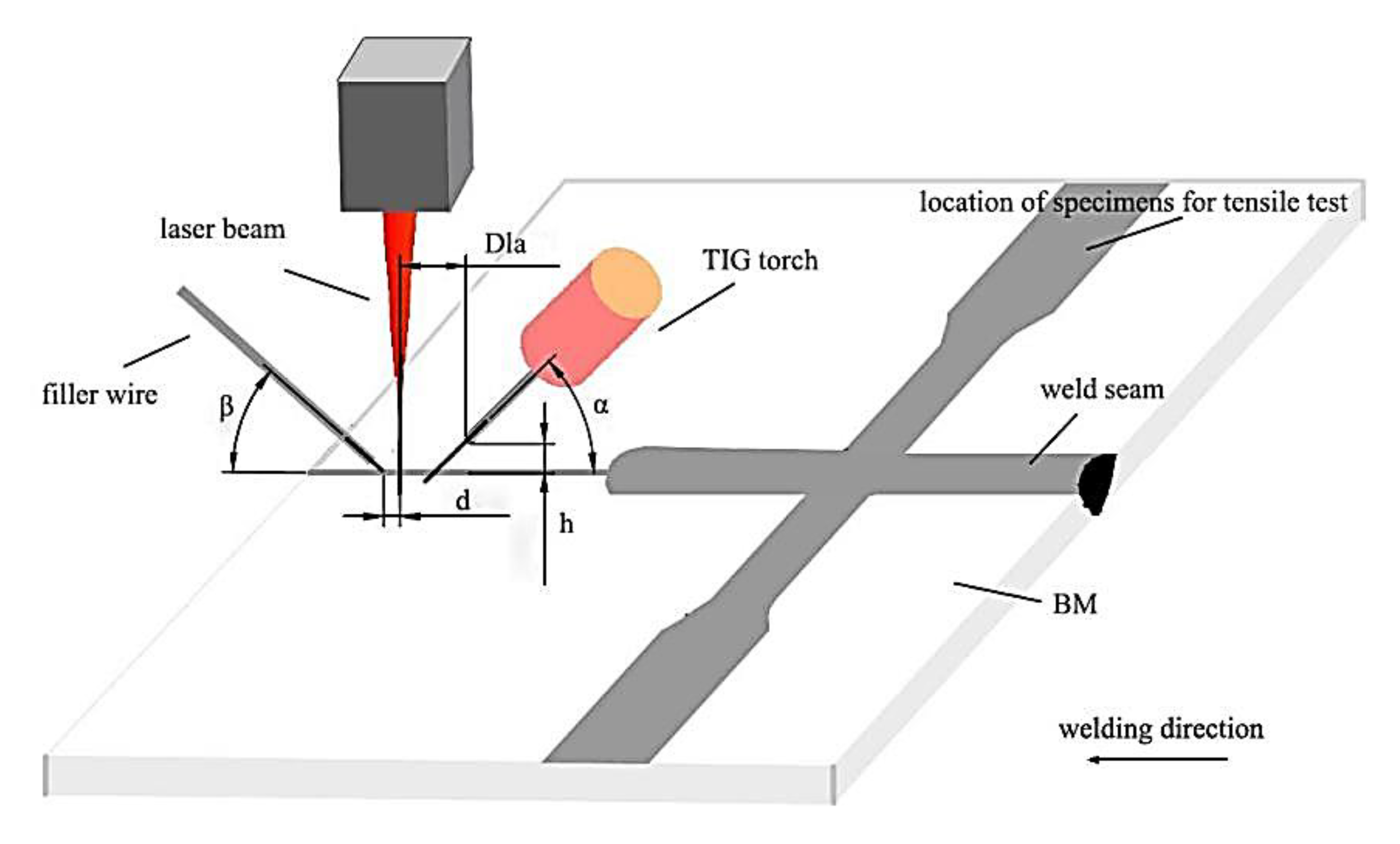

Laser beam welding can be used with crack sensitive materials such as the 6000 series of aluminum alloys when combined with an appropriate filler material such as 4032 or 4047 aluminum.

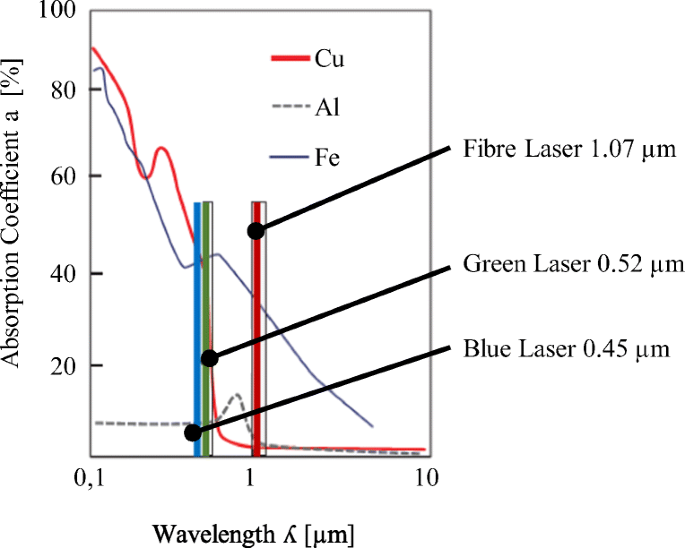

There are several different types of lasers that work well with aluminum and often the use of a cover gas is prudent.

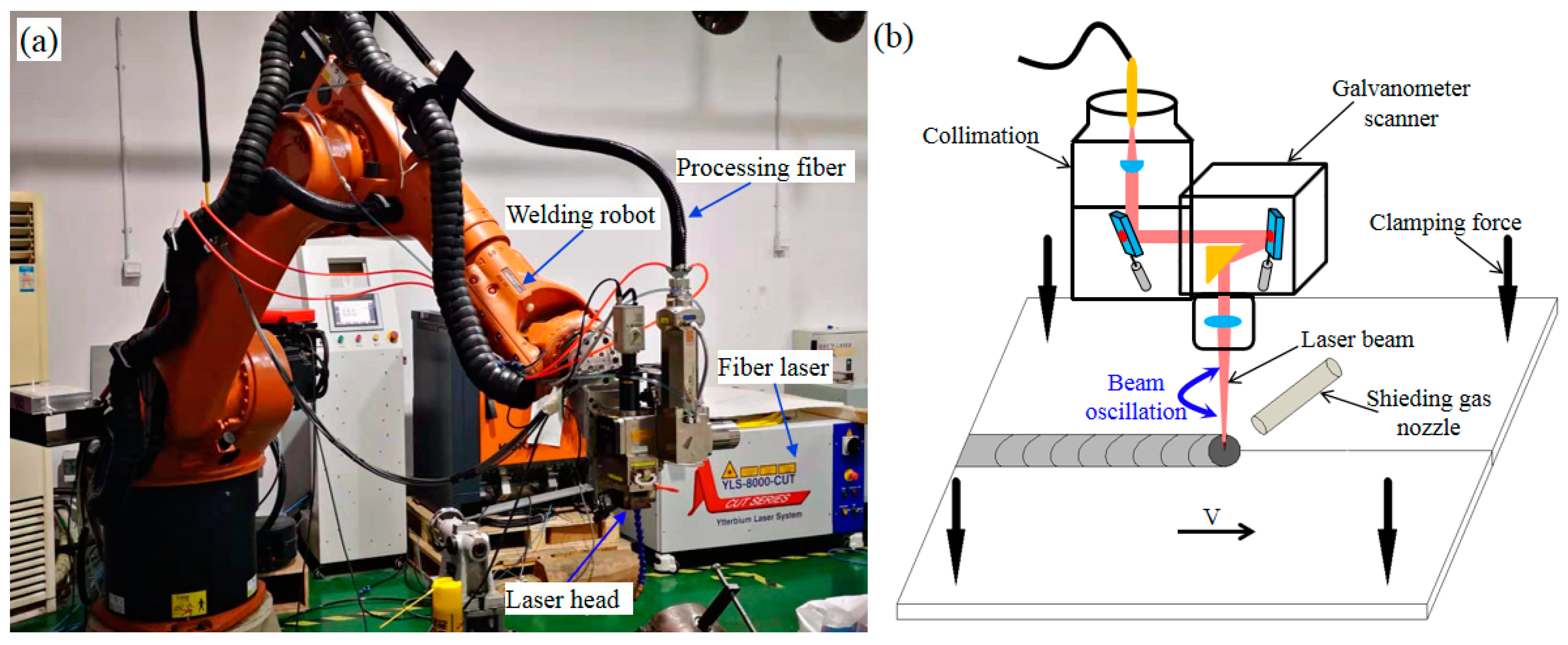

Morn handheld fiber laser welding machine also called handheld fiber laser welder portable fiber laser welding machine manual fiber laser welding machine is a new type high power high end continuous welding tool that couples a high energy laser beam into an optical fiber collimates it into parallel light through a collimating lens after long distance transmission and then focuses on the.

1 acceptable weld qualities are specified in the workmanship standard bs en 13919 welding electron and.

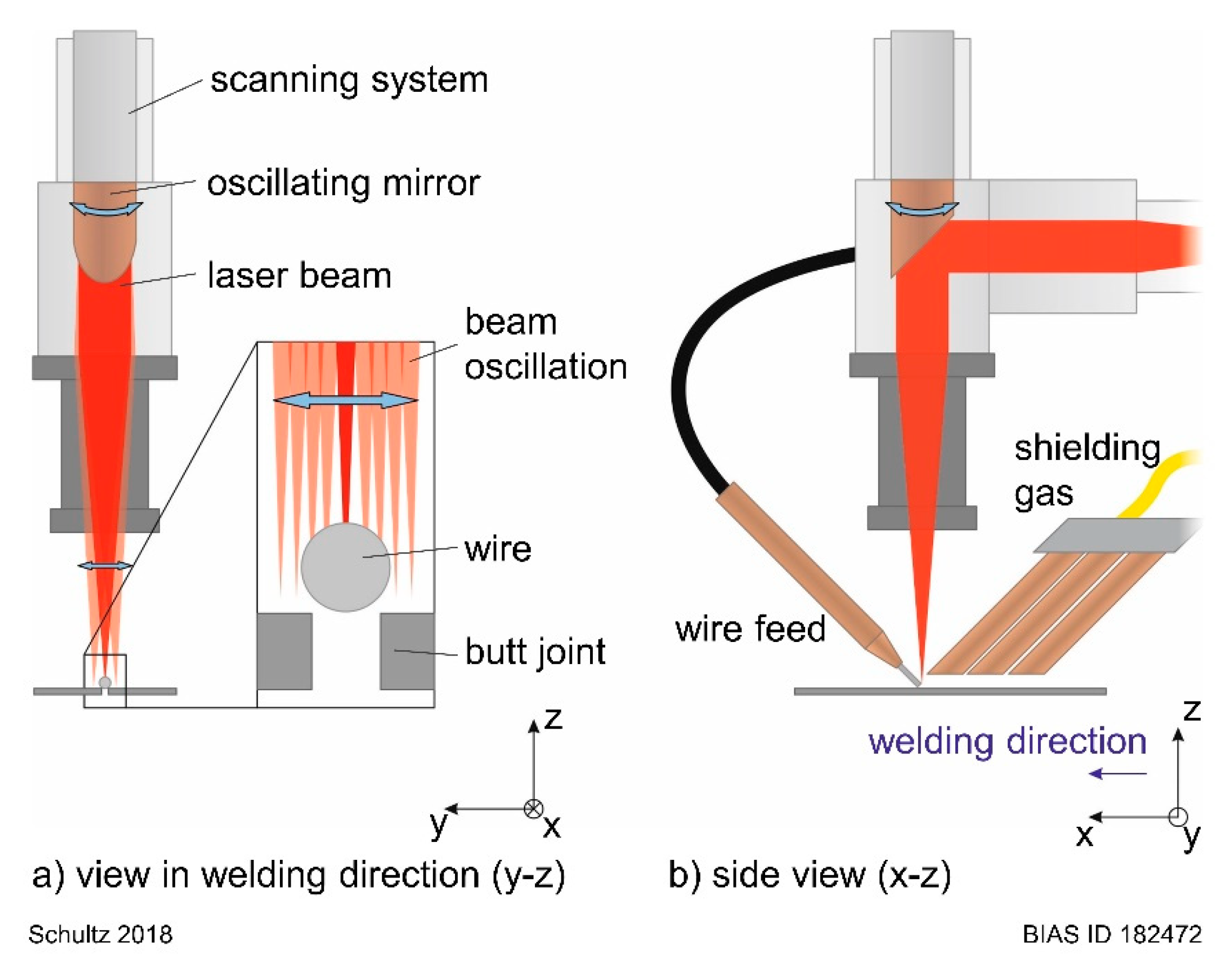

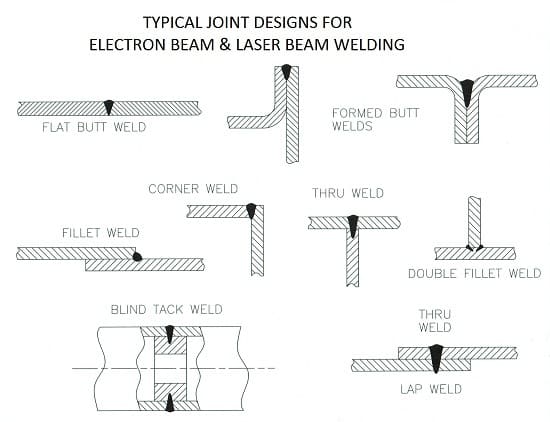

Joint configurations examples of sheet metal joint configurations suitable for laser welding are shown in fig 1 however to get an acceptable joint profile and weld quality 1 a number of processing and fit up conditions have to be satisfied table 2 some examples are given below.

However with the evolution of high power good beam quality carbon dioxide co 2 lasers and the advent of high power high brightness solid state fiber delivered lasers coupling the energy into aluminum is no longer an issue.

Properties aluminium alloys are increasingly being employed in many important manufacturing areas such as the automobile industries aeronautics and the military 4 6.

The electrons of an electron beam on the other hand are too energetic to be deflected significantly by the plasma.

The process is frequently used in high volume applications using automation as in the automotive industry it is based on keyhole or penetration mode welding.

Friction stir welding fsw and laser beam welding lbw are noteworthy for their present use in commercial aircraft manufacturing 7 11.